I. Project introduction:

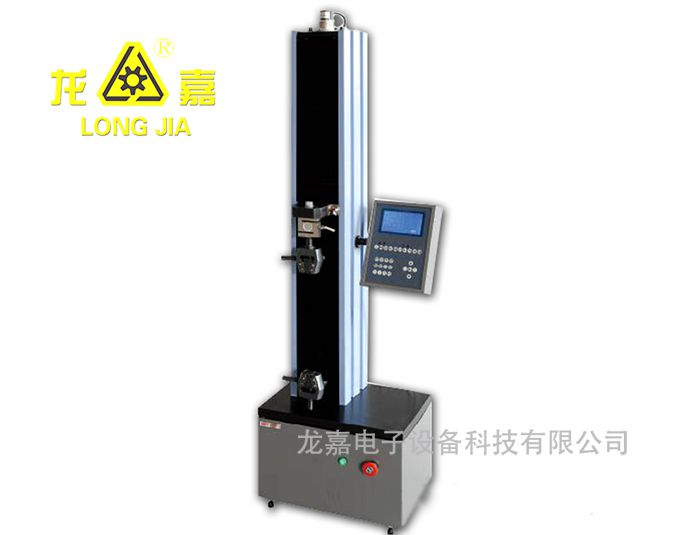

The domestic digital display electronic universal tester started in early 1990s. The Company is one of the companies that learn from foreign leading technology and research and develop electronic universal tester. To improve the technical level of the Company’s products, the Company has successively learned from advanced technologies at home and abroad, reaching a new high for the technical level of the Company’s products.

II. Scope of application:

The tester adopts TECO AC servo motor as power source; adopts advanced chip integration technology, and can test, analyze and study the mechanical properties of various metals, non-metals and composite materials. In addition, it is widely used in aerospace, petrochemical engineering, machinery manufacturing, wire, cable, textile, fiber, plastics, rubber, ceramics, food, pharmaceutical packaging, polyethylene-aluminum composite pipeline, plastic doors and windows, geo-textile, film, wood, paper, auto parts, metal materials and manufacturing.

III. Key description:

1. Host: The machine adopts a gantry floor-type double-spaced structure, pulls up and pushes down, regulates the speed steplessly by lifting and lowering the beam, and can change the test space after the replacement of uprights, lead screws and outer cover. The transmission system is composed of low-noise arc synchromesh gear belt deceleration system and lead screw pair, which is characterized by stable operation, high efficiency, low noise and no pollution.

IV. Attachments:

2. Standard configuration: A pair of lever-type stretching attachments. The lever-type stretching attachments adopt the manual clamping method, making it convenient and reliable to clamp without slide. The jaw remains immobile and the clamp part moves up and down in the clamping process. In addition, the sample is free from additional force, ensuring the accuracy of test results.

3. Wedge-shaped tensile fixture: Either horizontal vice jaw: 0-7mm (optional: 7-14mm) or round jaw:¢4-9 (optional: 9-14mm)

4. A set of compression attachments: Diameter of compression plate: 100mm

V. Functions

Automatic calibration: The system can automatically calibrate the scale value.

In the entire test process, the big LED displays the test force, peak value, displacement, speed and status in real time.

Breaking judgment: The movable cross-beam automatically stops moving after sample breaking.

Position limitation protection: It has the function of position limitation protection at machinery and control levels

VI. Main technical indicators

1. Maximum test force: 50KN

2. Tester class: Class 1

3. Allowable error limit of indicating value of test force: Within ±1% of indicating value

4. Range of load measurement: 2%~100% of full scale

5. Limit error of indicating value of displacement: Within ±1% of indicating value

6. Displacement resolution: 0.01m

7. Adjustable range of displacement speed: 0.01-300mm/min

8. Control accuracy of displacement rate: Within ±1% of set value when the rate is ≥1mm/min

9. Effective test width: 400mm

10. Effective distance of space of tension: 0-800mm

11. Dimensions of device host (L×W×H): 760×530×1830 (mm)

12. The movable cross-beam automatically stops moving (or automatically returns to the initial position) after sample breaking

13. Have the function of position limitation protection at program control and machinery levels

14. Automatic stop when the load exceeds 3~5% of rated value

15. Power supply: 220V, 50Hz, 750W

16. Net weight: 420Kg

VII. Configuration of tester host

1. A 50kN high-strength host

2. A high-precision optical-electricity encoder

3. A set of high-precision AC servo speed regulating system and a set of AC servo speed regulating motor

4. Two sets of high-precision ball lead screw pairs

5. A set of high-precision arc synchronous deceleration system

6. A 50kN high-precision spoke sensor

7. A set of stretching attachments dedicated for the tester

Power Frequency EDM

Power Frequency EDM  KH-300 Heat Aging Test Chamber

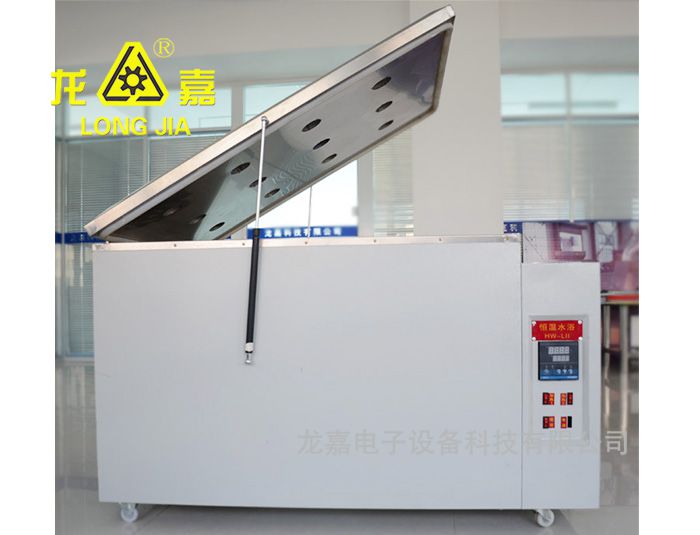

KH-300 Heat Aging Test Chamber  HW-II Type Thermostatic Waterbath

HW-II Type Thermostatic Waterbath  5T Digital Display Electronic Tensile Machine

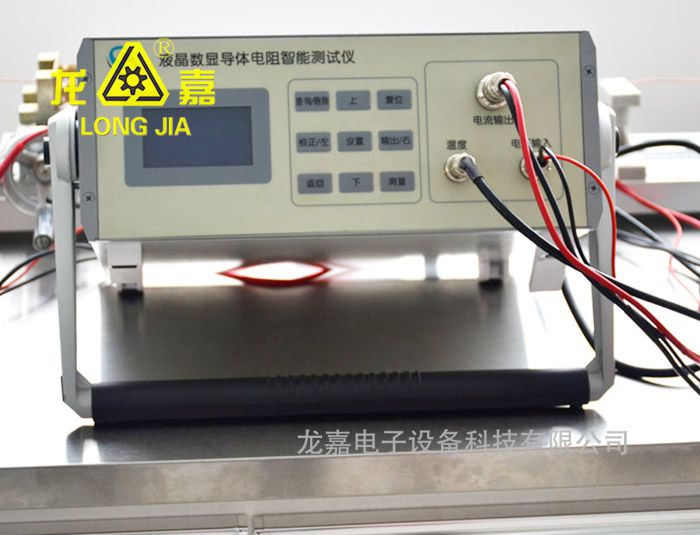

5T Digital Display Electronic Tensile Machine  QJ36 Intelligent LCD Conductor Resistance Tester

QJ36 Intelligent LCD Conductor Resistance Tester  LDS-5 Electronic Tensile Test Machine

LDS-5 Electronic Tensile Test Machine  QJ57 DC Resistance Bridge

QJ57 DC Resistance Bridge  QJ57B Intelligent Resistance Measuring Meter

QJ57B Intelligent Resistance Measuring Meter  PC36C DC Resistance Tester

PC36C DC Resistance Tester  ZC36 Type Highly-Insulated Resistance Measuring Meter

ZC36 Type Highly-Insulated Resistance Measuring Meter  ZC-90 Series Highly-Insulated Resistance Measuring Meter

ZC-90 Series Highly-Insulated Resistance Measuring Meter  LJ-FZ300 Wire And Cable Load Tester

LJ-FZ300 Wire And Cable Load Tester Xingtai Longjia Electronics Technology Co.,Ltd.

Copyright © Xingtai Longjia Electronics Technology Co.,Ltd. Todos los derechos reservados | Mapa del sitio |Energizado por